FIRST Alumni Make Manufacturing More Accessible with 3-D Printing Startup

FIRST Alumni Spotlight: Jonathan Schwartz and Max Friefeld, Co-Founders, Voodoo Manufacturing

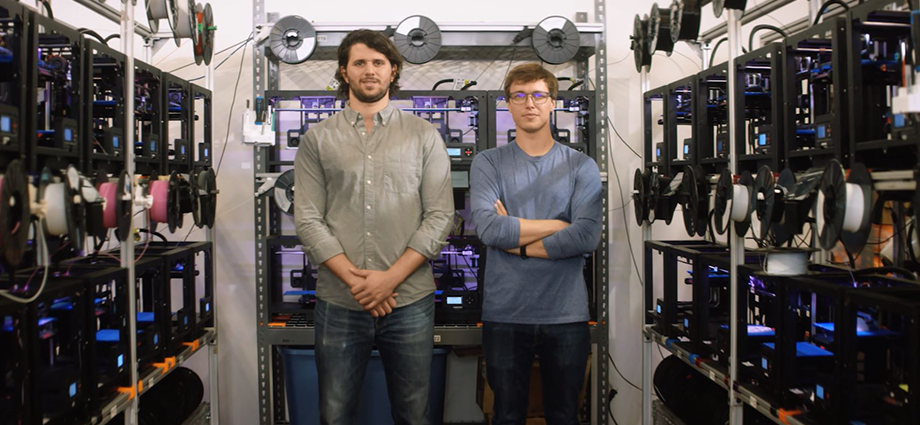

FIRST Alumni Jonathan Schwartz and Max Friefeld at their company, Voodoo Manufacturing, in Brooklyn, N.Y.

Jonathan Schwartz and Max Friefeld, co-founders of Voodoo Manufacturing, grew up on opposite U.S. coasts, but they shared a passion for engineering and robotics early on: They both attended public high schools specializing in STEM and joined FIRST Robotics Competition teams: Max was a member of Team 687, “The Nerd Herd,” from Carson, California; Schwartz was a member of Team 1520 “Omega - 13” in New York, New York.

Schwartz and Friefeld bonded over their shared passion for engineering, robotics, and entrepreneurship as students at FIRST Scholarship Provider Harvey Mudd College. They started a 3-D printing software company as college seniors – and as the desktop 3-D printer market was exploding. The company was a marketplace for 3-D printing hobbyists to purchase single prints of designs. They eventually sold the company to MakerBot, but their mission was unfinished: They ultimately wanted to create a business that would make manufacturing through 3-D printing accessible to everyone, not just enthusiasts.

Three years ago, they started Voodoo Manufacturing, a Brooklyn-based robotic 3-D printing factory that manufactures everything from promotional phone cases to prosthetic hands quickly, in quantities up to 10,000. “It’s about the power to have an idea or a need, and then make that happen,” Schwartz said. “That power has never been as accessible as it is right now. At Voodoo, we’re trying to make that experience possible for everyone.”

FIRST Alumni Jonathan Schwartz and Max Friefeld are featured at the Voodoo Manufacturing factory in this “I AM FIRST” video.

This month, tens of thousands of new FIRST Alumni are graduating high school and launching their next adventures. We asked Schwartz and Friefeld their advice for FIRST Alumni about starting their careers and businesses and what inspired them to launch Voodoo as young engineers.

Q: When did you first use a 3-D printer?

Schwartz: We were both lucky enough to have used 3-D printers in high school. My first class in high school was an engineering drafting class, and one of the projects was to reverse engineer a LEGO brick, CAD it, and print it out. I was just amazed by it. I didn’t know that years later I would start a company around 3-D printing, but I had the exposure to it early.

Voodoo Manufacturing is a robotic 3-D printing factory located in Brooklyn, N.Y.

Friefeld: We take it for granted, but the first time we ever designed something in CAD we were able to just click print. We didn’t have to know about manufacturing. That is a really cool experience that most people 10 years older than us never had.

Q: You started Voodoo after you created and sold another company. What inspired Voodoo?

Schwartz: What inspired Voodoo was we saw an opportunity to use desktop 3-D printers in a way no one had before. Most service bureaus were using high-end commercial or industrial 3-D printers, and they primarily serviced the market of high-value, low-volume parts. We had this different background of using the low-end machines, and we thought they were pretty good, as long as you target the right kinds of parts and products. We could also build software tools and products. So we were crazy enough to realize we could build a factory with hundreds of these printers and run it effectively enough to produce parts that are cost-competitive with other factory parts.

Q: How is your work at Voodoo changing the world?

Schwartz: Our vision is to give everyone on Earth the power to manufacture. We think by doing that we will enable people to design products that are better, which will improve the lives of everyone that uses those products. Today, manufacturing is a very wasteful industry – waste that happens in the factory with overproduction, in transportation when moving products, and in extra inventory. We think that with the type of factory we’re building, it’s going to significantly reduce those wastes, since everything is on demand: You get the volume you need when you need it and it’s much more local to where you need it. We also work with a third party to recycle all of our filament and turn it back into new filament, so we really try to do everything we can to reduce our footprint.

Q: Max, what inspired you to join your school’s FIRST Robotics Competition team?

Friefeld: One of my best friends in middle school told me his older brother was on a crazy thing called a robotics team. I was like, “I need to do this.” I was into tinkering and building things with my hands at that point. I didn’t really know what engineering was as a profession until I joined FIRST, so the mentors really taught me what it meant to be an engineer. My team was more focused on community outreach than winning; we ran summer camps and other activities to get lots of people involved in STEM and FIRST.

Q: How did your team’s focus on outreach over winning impact you?

Friefeld: I learned how to teach complex problem solving, leading younger students through complex and difficult subjects that don’t have obvious answers at the beginning. It was one of the most enjoyable parts of being on the team. I also learned a lot about failure. Our mentors were not afraid to watch us lose, probably knowing the entire time what was going to happen. I learned to be ok with that, and to rely on myself and my team to get things done. This had a strong impact on my willingness to go into the startup world because failure is the outcome 90 percent of the time.

Q: Jon, what did you take away from your FIRST experience?

Schwartz: I remember going through so many Iterations of our design and testing whether these concepts were even feasible. It really taught me how to be an engineer in the sense of understanding how to approach problems and what the engineering process looks like, from design to building to testing to having something that works.

Jonathan Schwartz works on a 3-D printer at Voodoo.

Q: Do you have a favorite memory from your FIRST team?

Friefeld: One year, my team really wanted to get the Engineering Inspiration Award [to qualify for FIRST Championship]. We were putting together this technical data package about the robot, and like typical high school students, we left it to the last minute. We pulled an all-nighter the night before the competition putting the whole thing together. We were so proud of this document. It was this remarkable experience of teamwork that I didn’t feel again until starting a company.

Schwartz: My best memories are similar in that they were the late nights where we would be eating pizza banging our head against some problem. That was really the most fun and most rewarding part of FIRST. You’re not just doing it by yourself, but doing it with other people: your teammates.

Q: What advice do you give young people about setting themselves up for a successful career in the 21st century?

Friefeld: I feel strongly that engineering provides a framework to think about and solve problems – whether that’s an engineering problem, a business problem, a marketing problem. If I were hiring a marketer and I could choose between someone who studied engineering and somebody who didn’t, I would hire the engineer because I value the skill set and I think the world does, too.

Q: Any advice for young entrepreneurs about going into business with friends?

Friefeld: The number one reason startups fail is because of a founder breakup or issue. Jon and I became friends as we started the company, so we often say we got very lucky because either of us could have turned out to be people we didn’t expect in the process. In general, I tell people to put a high barrier on who they start a company with and really prove out to yourself that it makes sense before you dive in.

Q: Why do you think you work well as a team?

Schwartz: Max and I have very complimentary skill sets. We’re very different in some ways and very similar in others. For example, Max is more analytical than I am; I’m a little more creative than he is. But we’re both engineers, so we both approach every problem from an angle. We’re able to work together and get on the same page very quickly. We’re also able to take ownership over different tasks, knowing that one of us might be stronger than the other.

If you have an inspiring story or piece of wisdom that you’ve picked up through your experiences in the FIRST community, please reach out to us at inspire@firstinspires.org and inquire about becoming a guest contributor for Inspire.